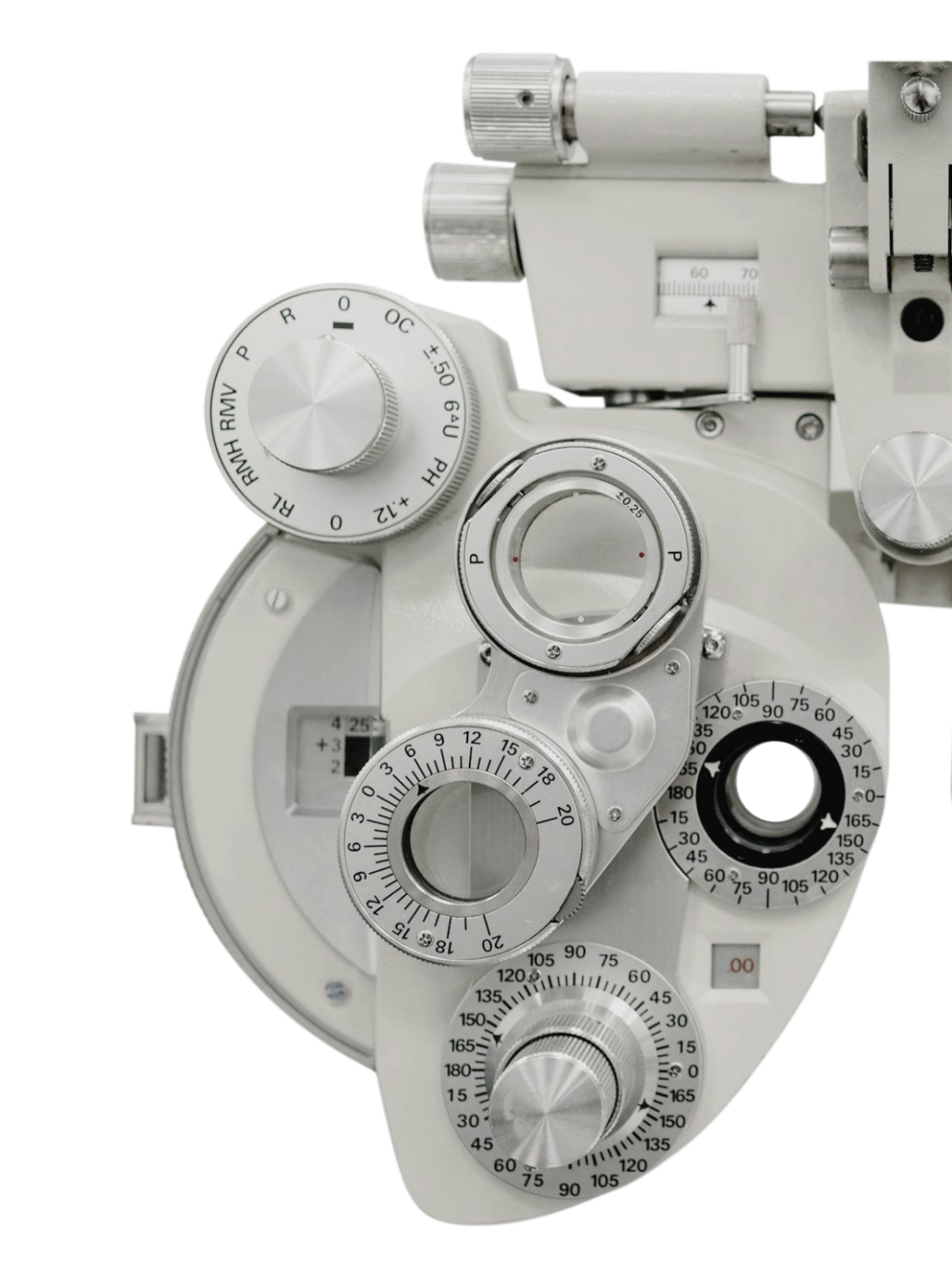

Welding glasses with protection

At Pegaso, we are experts in occupational eye safety and specialized manufacturers, which allows us to design the most suitable models for welders. We offer a wide range of professional welding protection glasses, from neutral models to prescription and goggle covers. All our options have different DIN intensity levels, ensuring the ideal choice according to the specific needs of each job.

Prescription Safety Glasses for companies

Benefits for the company

Benefits for the employee

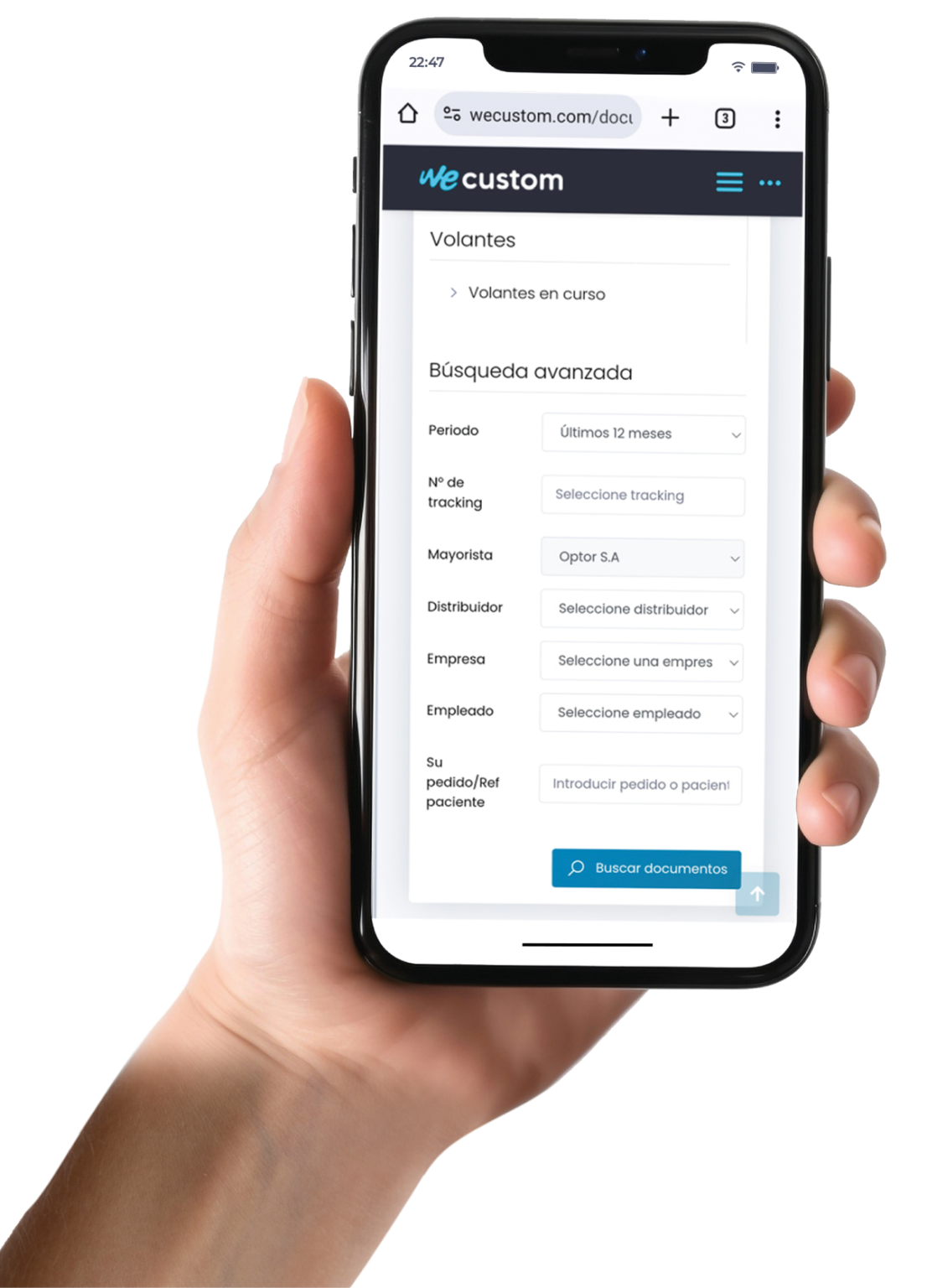

Your prescription safety glasses in one click

Latest TECH performs better

1

The person in charge of HSE in the company fills out the application form.

2

The optician receives the application and graduates the employee.

3

Manufactured in

7 working days.

Pegaso for companies

Contact us and rely on more than 70 years of experience in occupational safety and eye protection.

Fernando García

Sales Manager

fgarcia@pegaso.es

Tel: 932 04 81 10

Lucía Alonso

International Customer Service

lucia@pegaso.es

Tel: 932 04 81 10

Frequently asked questions about prescription safety glasses

| Welding processes generate intense ultraviolet (UV) and infrared (IR) rays, invisible to the human eye, but capable of causing immediate eye injuries, sometimes without us even realizing it. Therefore, it is essential to use goggles with an appropriate protective filter, which allow the welder to clearly see the metal he is working on. These goggles also have side shields to prevent sparks from reaching the eyes. |

| Más que el precio, lo importante es elegir el filtro adecuado para la intensidad y tipo de soldadura que se realice. A mayor intensidad o duración de la soldadura, se requiere un nivel de oscuridad más alto, determinado por los valores DIN. |

El DIN indica el grado de filtración de la lente y está regulado por la agencia DIN (Deutsches Institut für Normung). La escala varía de 1 a 15:

Each welding technique produces flames with different characteristics and specific emissions in the UV and IR spectra. Therefore, it is essential to select the lens that can withstand the intensity without compromising protection. If you are in doubt about which DIN is best suited to your job, our team will be happy to advise you. |

|

Check out our catalogue to explore the features of our welding glasses and select the ideal option for your job. |

Welding involves mechanical, chemical and radiation risks. These threats can cause:

|

| It is a visual discomfort caused by excessive exposure to intense welding light, which can reduce the ability to distinguish objects and, depending on the exposure time, become disabling. |

| The level of darkness depends on the flow rate and intensity of the welding machine. Typically, filters between DIN 3 and DIN 7 are used, although the specific value may vary depending on the task. |